OUR PRODUCTS

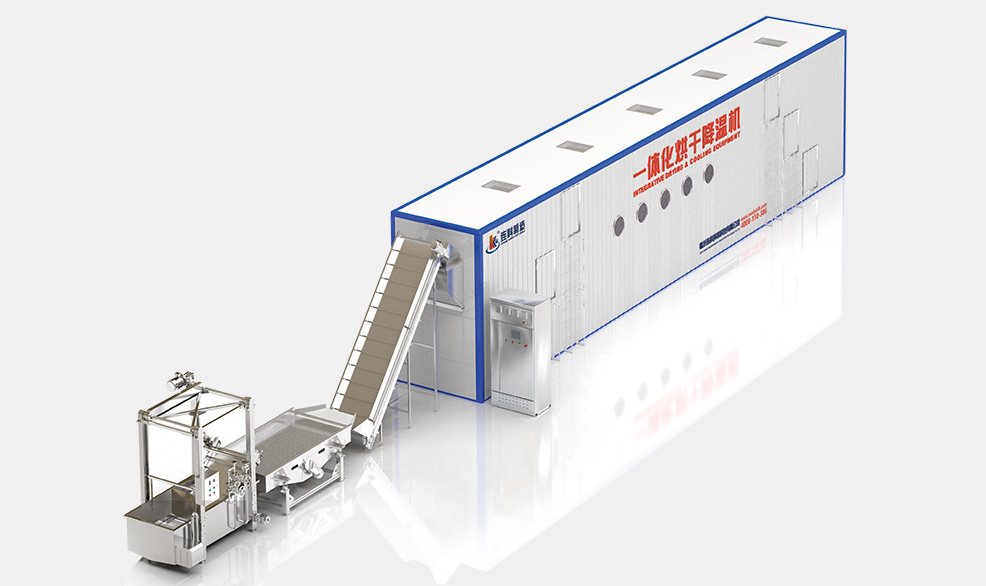

Integrated full automatic drying and cooling machine

Full automatic sausage cleaning and drying production line is made up of automatic pouring machine, bubble cleaning machine, vibrating dewatering device, climbing belt conveying line, integrative drying and cooling machine. Used for cleaning the sausage surface residual and oil stain, realize sausage rapid drying; avoid the sausage both sealing ends go mouldy.

Equipment characteristic:

1.Full automatic sausage cleaning & drying production line characteristic

2.Adopting by low temperature drying to ensure the good taste and quality

3.Innovative sanitation design, realized quick cleaning of the equipment, avoid bacteria residual

4.Integrated design and closely combined with sausage manufacturer, by the multiple test and constantly upgrade, maximization matching the processing characteristic during the sausage production.

Technical parameter

1.New generation drying machine

| Model | Capacity | Overall dimension | Main unit power | Refrigerating unit power | Steam consumption |

| LK-HG-10 | 1.0T/h | L8000×W2300×H3400mm | 16kw | 15kw | 0.5T/h |

| LK-HG-20 | 2.0T/h | L12000×W2500×H3400mm | 27kw | 30kw | 0.25T/h |

| LK-HG-30 | 3.0T/h | L12000×W2900×H3400mm | 48kw | 43kw | 0.3T/h |

| LK-HG-60 | 6.0T/h | L12000×W5000×H3400mm | 96kw | 86kw | 0.5T/h |

| Non-standard model customized according to customer requirement | |||||

2.Automaitc constant temperature bubble cleaning machine

| Capacity | Heating temperature | Steam consumption | Main body material |

TotalPower

|

Overall dimension |

|

Maximum 3T/h,adjustable

|

30℃-50℃ Automatic constant temperature

|

0.1-0.2T/h | SUS304 | 2.6kw | L2700×W1580×H2795mm |